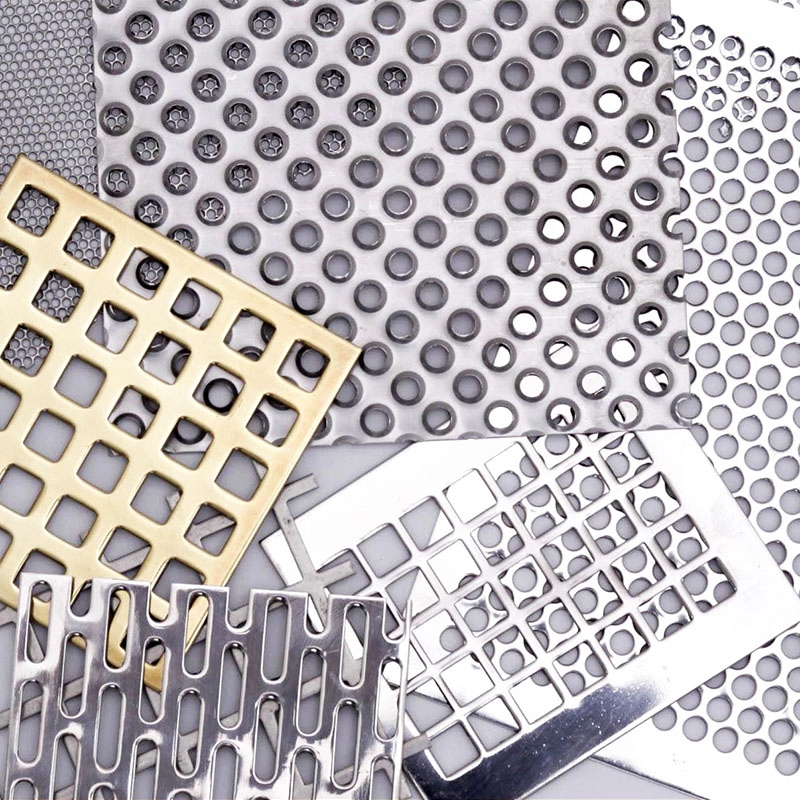

Its resistance to rust, heat, and wear makes it ideal for harsh environments. Whether used for architectural facades, industrial sieves, or safety barriers, stainless steel perforated mesh combines functionality with a sleek, modern appearance.

Applications and Benefits of Stainless Steel Perforated Metal Mesh

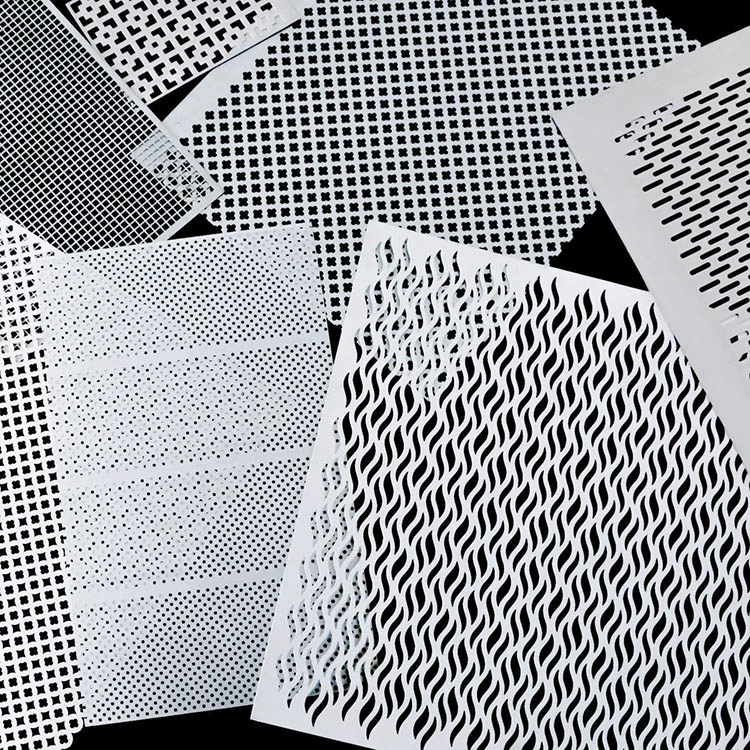

Stainless steel perforated metal mesh is a versatile solution for numerous industrial and commercial applications. In architecture, it is used for decorative facades, sunshades, and balcony railings, providing both visual appeal and structural support. The food and beverage industry relies on it for sorting, drying, and filtration due to its hygienic, non-reactive properties. Industrial uses include machine guards, vibrating screens, and conveyor belts, where durability and precision are essential. Automotive manufacturers incorporate it into grilles, exhaust systems, and ventilation components for its heat resistance and airflow efficiency. Additionally, it serves in acoustic panels for noise control and in agricultural equipment for sieving and grading.

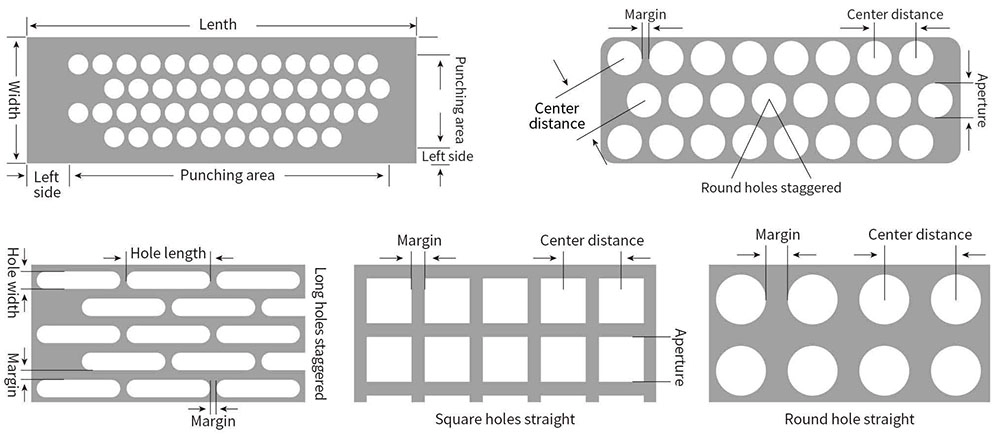

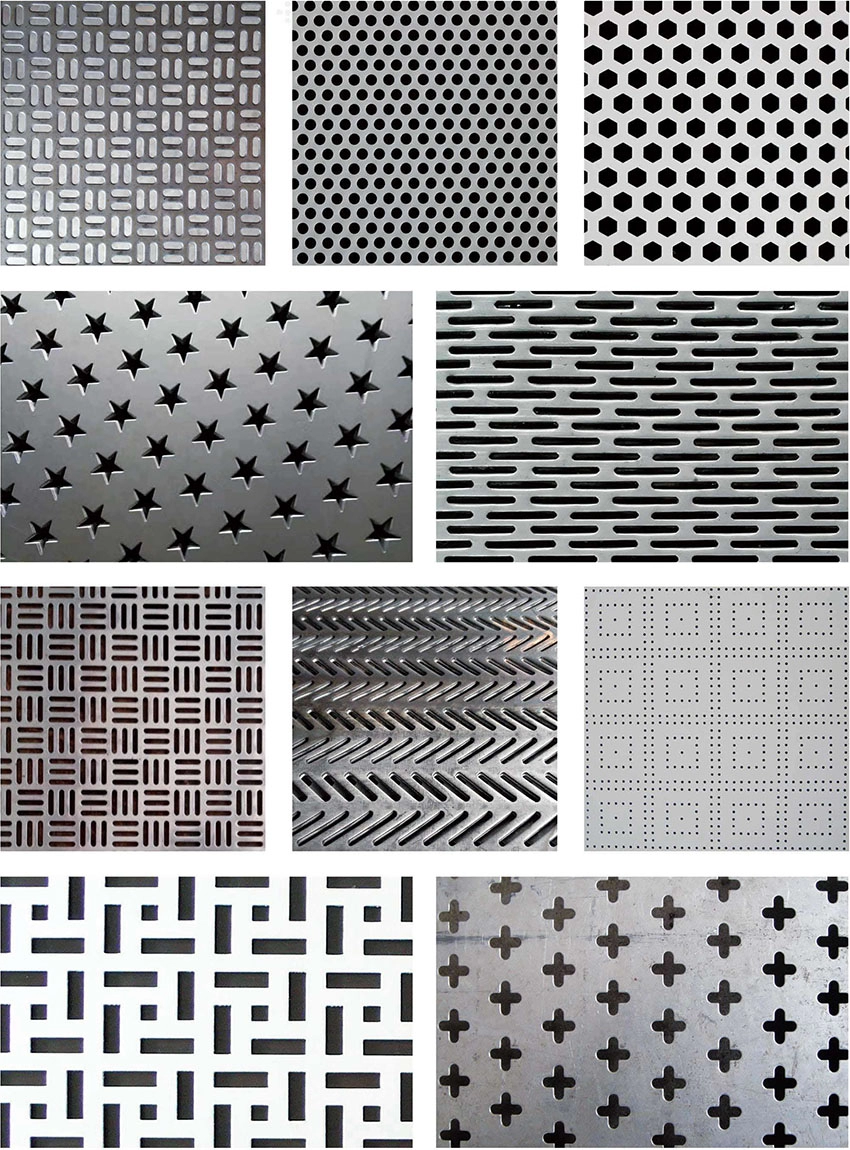

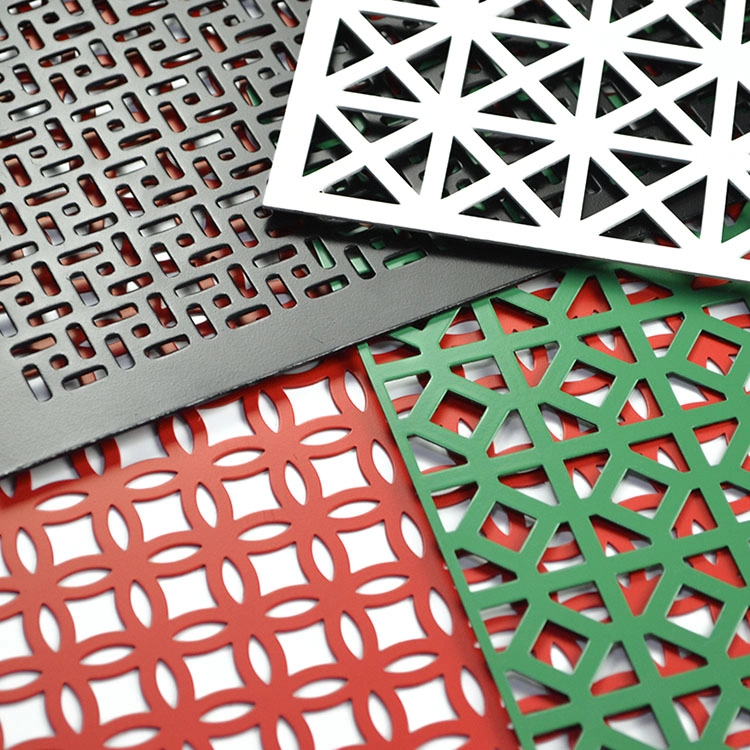

One of the primary advantages of stainless steel perforated mesh is its exceptional corrosion resistance, making it suitable for outdoor and high-moisture environments. The material retains its strength under extreme temperatures, ensuring reliability in industrial furnaces or refrigeration units. Customizable hole sizes and patterns allow for tailored solutions, whether for fine filtration or decorative designs. Its easy maintenance and long lifespan reduce replacement costs, while its recyclability supports sustainability. Lightweight yet robust, stainless steel perforated mesh is easy to install without sacrificing performance. Combining functionality with aesthetic flexibility, it remains a top choice for engineers, architects, and manufacturers seeking a high-performance, low-maintenance material.